The difference between greywater and blackwater onsite water reuse systems

Onsite water reuse is the process of collecting, treating and reusing wastewater within the same building or community in which it is produced (at the source), instead of sending it to the sewer for treatment at a centralized municipal facility. Onsite reuse closes the loop for urban water systems and works seamlessly within the existing, centralized water infrastructure, adding resilience to the water grid. Epic Cleantec provides water recycling solutions for all wastewater sources, with systems custom-designed to fit each building or community so that they become more self-sufficient in their water use and needs.

A building’s onsite water reuse system can be designed to collect greywater or blackwater. The essential treatment technologies for each approach are very similar with Epic Cleantec’s MBR-based treatment steps, and both greywater and blackwater reuse play a role in sustainable water practices and environmental conservation. When deciding which system is best for your project, there are several key considerations that can affect the overall decision-making process.

Considerations when choosing an onsite greywater or blackwater reuse system for your project

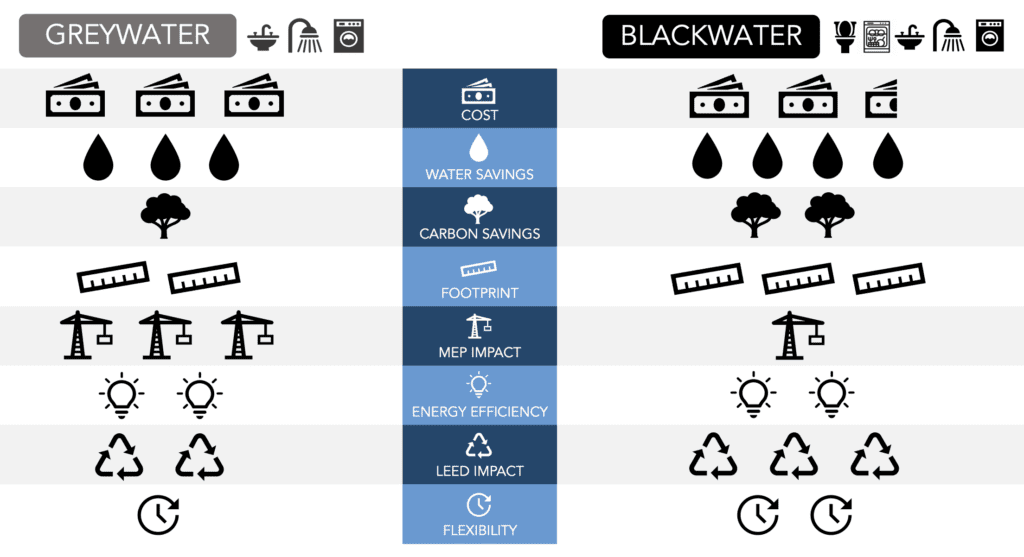

The below chart outlines some key comparative characteristics of greywater and blackwater systems.

This is structured to compare first costs of greywater and blackwater system installations to each other; it is not, for instance, structured to compare either system to a rainwater system.

Cost and ROI of greywater and blackwater systems

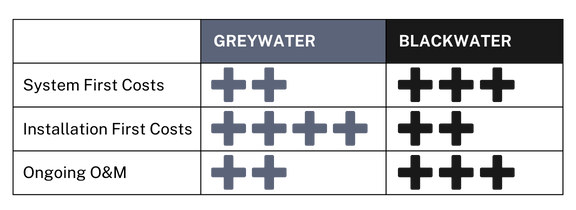

As shown in the graph, we typically see blackwater systems having an initial higher capital cost due to the additional equipment associated with blackwater systems. Blackwater may also have increased O&M needs due to the fact that most jurisdictions require regulatory sampling more frequently for blackwater systems than greywater, which can drive up O&M costs.

However, depending on the layout and size of the project, a greywater system can have an equally high or even higher first cost. This is due to the dedicated wastewater collection system that is required to separate the greywater fixtures from the blackwater, which increases the amount of piping on the project. In some projects, the added costs of this separated dual-plumbing can add hundreds of thousands of dollars to the overall cost. This will of course depend on the construction rates in the project’s jurisdiction. For specific project costs, request a free project assessment.

The return on investment (or “ROI”) of an onsite wastewater system is based on multiple factors, and the system treatment capacity is at the top of that list. Economies of scale drive system ROI due to the higher initial system and installation costs; larger projects with greater volumes of water result in greater utility savings, resulting in better ROIs. Typically, we see ROI in projects in 3-7 years. Learn more about how to calculate the ROI of water use in your projects.

Water savings potential in onsite water reuse systems

Since blackwater includes so many more sources of water than greywater, the volume of blackwater in a building will always be greater than the volume of greywater. However, it’s important to consider the overall water balance: the volume of recycled water demand versus the volume of wastewater supply. In many multifamily projects, if the building is using recycled water for only toilets and laundry, typically a greywater system will be able to supply 100% of the building’s non-potable demand, and blackwater sources would not need to be utilized. In that case, the project could either choose a greywater system for optimization or choose to supply additional non-potable end uses with recycled blackwater, such as cooling tower makeup or irrigation.

It is important to conduct the water balance analysis early in the project and to keep updating the calculations as design progresses so that the project owner will have an accurate sense of projected water and sewer bill savings. As discussed previously, the volume of recycled water produced is directly correlated with expected ROI.

Carbon savings through water reuse

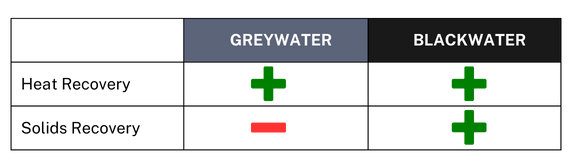

One method your project can achieve energy savings is through wastewater heat recovery, which is a process wherein the heat energy within the captured wastewater is captured and transferred to the building plumbing or HVAC systems via heat exchangers.

Wastewater heat recovery is both feasible and effective with both greywater and blackwater systems. Carbon savings are achieved through heat recovery because the building’s hot water and hydronic systems may be able to be reduced, leading to lower energy usage. Greywater typically has a higher energy recovery potential, because fixtures such as showers and washing machines are large sources of hot water, whereas blackwater fixtures (like toilets) are not.

Solids recovery is only possible with a blackwater system. Solids recovery is achieved upstream of the main treatment system through a microscreen, which filters out the wastewater organics in solid form through a pre screening process. The solids are collected by Epic operators and taken offsite to processing hubs where they are turned into high-quality soil amendments. The soil amendments can then be reused on the building property in garden landscapes or potted plants, putting carbon back into the ground and offsetting additional soil needs.

Footprint and system size

The footprint is dependent on the configuration of the specific room, the available ceiling height, and the type of water storage tanks. Tanks may also be located underground or exterior to the building for space savings. A smaller system may average around 500 sq.ft., while a larger system may average around 3,000 sq.ft.

Blackwater systems on average have larger footprints than greywater systems due to the additional treatment that is needed. Solids screening associated with blackwater systems may require up to an additional 300 sq.ft., which is typically located on the floor above the treatment system; however, solids screening also leads to optimized downsizing of the main equipment. Request a free project assessment for specific system and site sizing, as each system is custom designed and can be optimized to each site’s constraints.

MEP impact

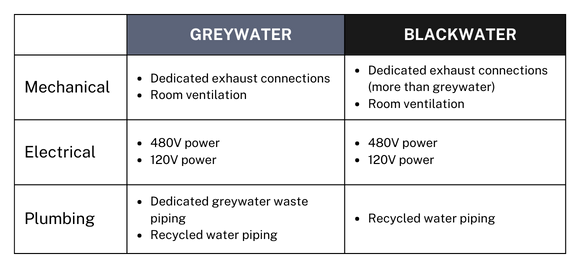

The dedicated system of greywater collection piping is typically a major consideration, as it increases the quantity of waste piping within the building. The chart below details some relative considerations that the MEP engineers will need for their own designs.

If the blackwater system includes solids screening, that will necessitate additional mechanical and electrical requirements. The other impacts to MEP are similar between greywater and blackwater systems. Note that while 480V power is the standard basis for some equipment, substitutions can be made to accommodate the available site power.

Energy efficiency expectations

For systems of the same size, expect a similar energy use between greywater and blackwater systems. Because each system’s energy requirements is dependent upon its size, Epic will walk you through what to expect for energy use when discussing your project specifics.

LEED impact

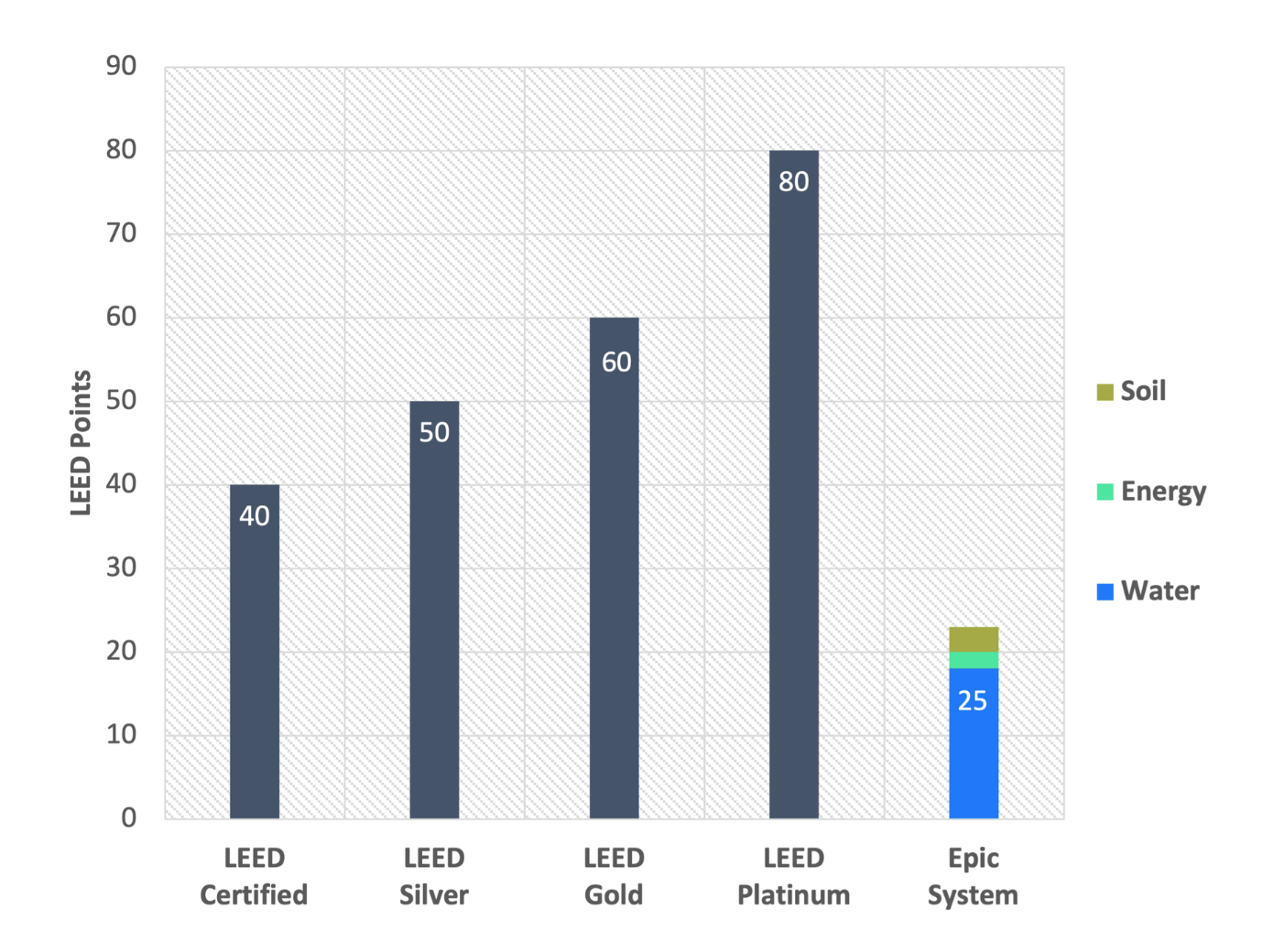

Both systems can expect to achieve LEED points for Water Efficiency credits, assuming that recycled water is used for indoor and outdoor end uses. Both systems can also expect to achieve credits (up to 18) for Innovation and Pilot Credits in water and wastewater efficiencies. Projects incorporating heat recovery may also expect credits in the Energy category, meaning you could earn up to 25 LEED v5 points for a blackwater + heat recovery system.

Blackwater systems, overall, will typically achieve more points than greywater systems, due to the higher volume of wastewater recovery.

Flexibility

Blackwater is considered the more flexible system, meaning it is more future proof. Modifications, tenant changes, and retrofits will benefit from having a single waste system, rather than a system for dedicated greywater fixtures.

While these considerations are not comprehensive, they should serve as a general outline for the design differences between greywater and blackwater onsite treatment systems. For more specific information or estimates related to an upcoming project, request a free project assessment from Epic Cleantec.